PACKAGING, PALLETIZATION

Which products can we palletize and package automatically or with the help of an industrial robot:

\ cardboard packaging / boxes,

\ sacks / bags,

\ bottles / jars / cans / cups,

\ buckets / plastic containers,

\ metal parts,

\ concrete elements,

\ wooden elements,

\ and many others.

solutions:

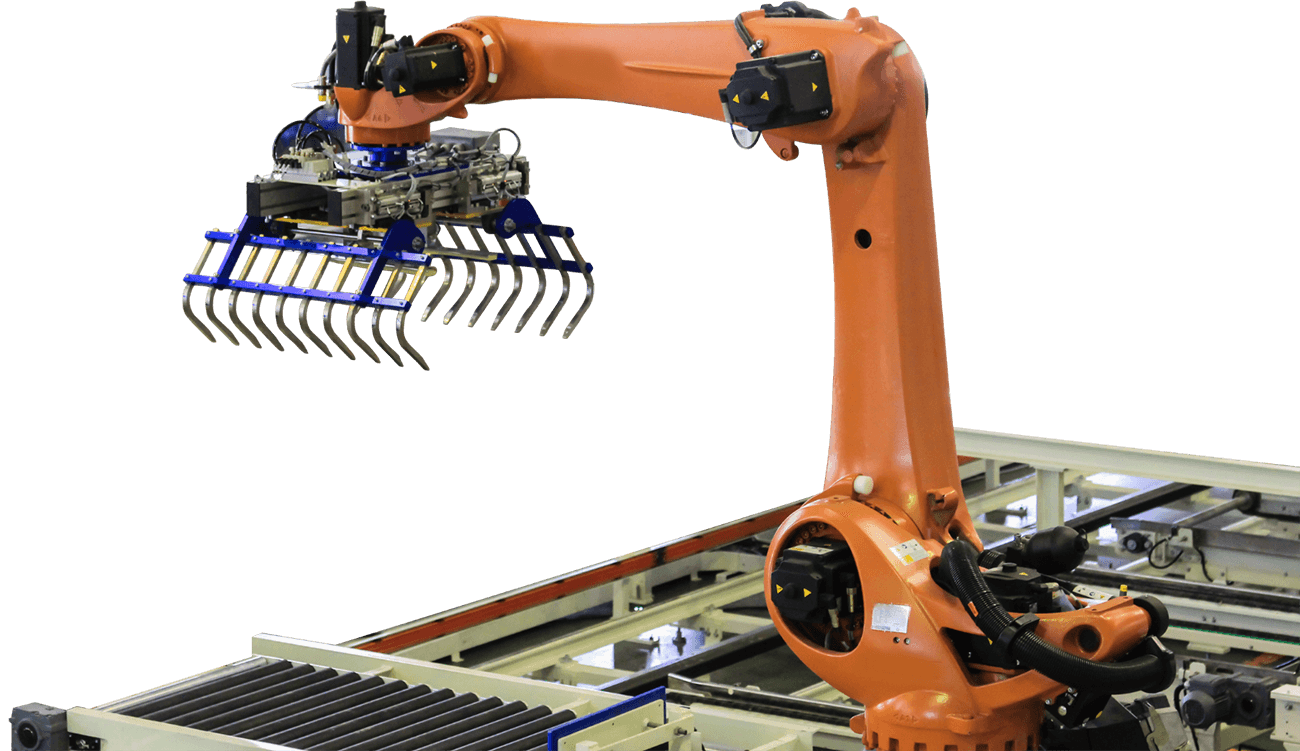

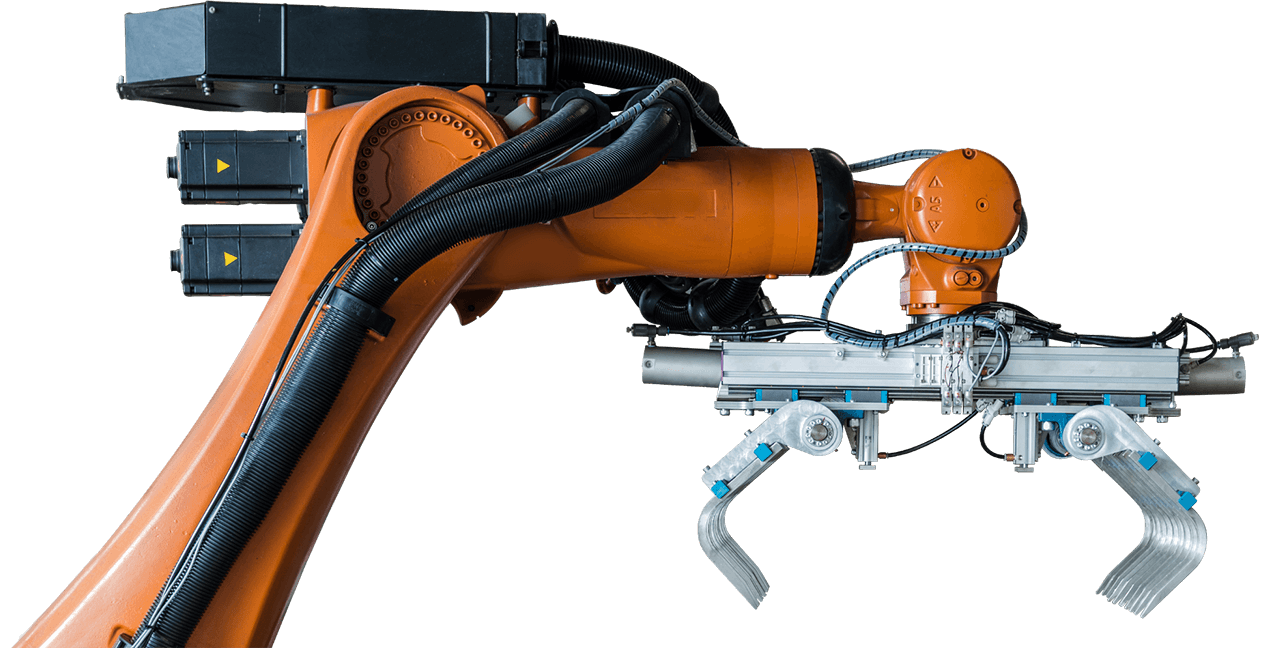

Types of packaging and palletizing heads used in palletizers, manipulators and palletizing robots:

\ mechanical heads,

\ vacuum heads,

\ hybrid heads (combination of gripping systems).

Additional options for installation in heads:

\ height / position compensators,

\ separators collection system,

\ layer / product search system,

\ pallet collection system,

\ product proximity detection system,

\ mechanical clamping system for holding / formatting the product,

\ head zone control system allowing for work with different sizes of elements with one head.

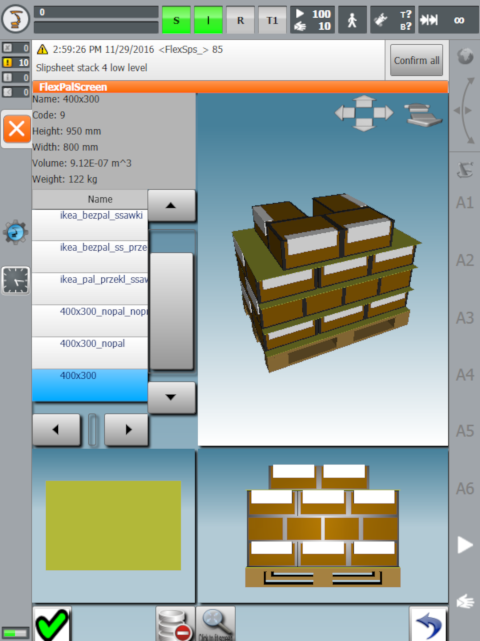

software:

Integrated graphic editors enable quick and intuitive defining of packaging, packages, pallets and grippers. They allow faster generation of sections, storage compartments, position systems and stacking schemes. They facilitate the creation of new palletizing schemes based on already used patterns.

Such technological software significantly simplifies and speeds up the configuration

and creation of programs related to palletization

and also de-palletization of products.

The basic advantages of using technological software are:

\ the ability to freely define elements such as products, packaging areas, pallets, etc.,

\ the ability to define the type of grippers,

\ the ability to assign a particular type of gripper to a palletizing program,

\ quick creation of stacking patterns and schemas,

\ quickly adding new products packaging to an already used station.

Our robotized applications are able to palletize or de-palletize products from most industries. Dedicated 5 and 4 axis palletizing robots have a positive effect on lower costs of robotization, packing line ends.

Well designed and implemented solutions allow for a significant increase production efficiency, eliminating bottlenecks that are often palletizing and packaging areas. Robots can carry out various tasks at the packaging station, e.g. collecting pallets and separators, picking and formatting product layers on a pallet. Furthermore, changing the pallet format or changing the collective packaging needs only to change the execution program. While the retooling of a classic machine requires downtime of technical staff to modify and replace formatting elements. By using automatic packaging and palletizing solution, we are able to achieve the rated capacity of production machines.

palletizing station:

The elements of the basic packaging and palletizing station are:

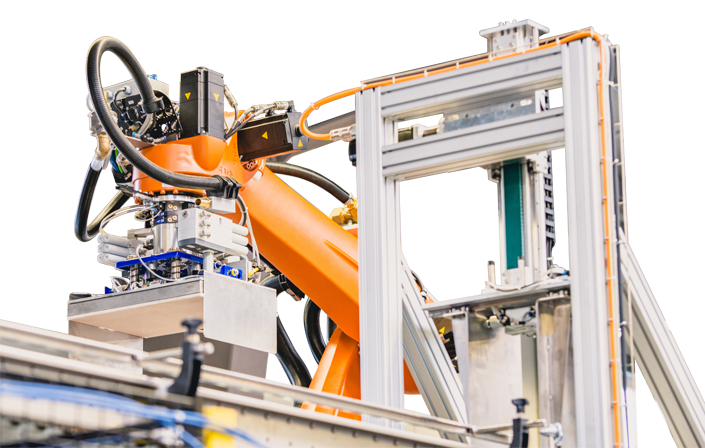

\ robot or multi-axis manipulator,

\ head dedicated to work with a specific product,

\ product stacking / palletizing area,

\ pallet dispenser,

\ separators dispenser,

\ safety fence,

\ product inputs conveyors to the station (e.g. transporter),

\ system for ready product / pallet transport outside the station,

\ automation, pneumatics and safety systems.

In current conditions, there is often demand to pack so-called "mixes". These solutions are based on two stations of products de-palletizing and palletizing or as a ready solution for standard and "mix" type palletizing in one packing end.

The packaging and transport systems developed by our team can be equipped with product detection systems by means of vision system or 2D codes readers. Moreover, we equip robotized cells with systems for automatic marking, sorting, wrapping or shrinking and buffering of products and collective packaging. All elements of the station are connected together by industrial network and available for the operator from a single control panel. We also develop and implement SCADA type software for supervision of entire production lines.