Universal robotized welding cell for MIG/MAG processes.

We designed and implemented an universal MIG/MAG welding cell for the Mielec branch of the Alpha Technology Company. We carry out welding processes for frames constructions using a welding robot. The technical requirements of the application are presented below:

- elements of black steel manufactured by means of MIG/MAG welding technology,

- welding frames constructions up to 4.3m length (assuming 4.8m of space between the turntable flanges),

- the possibility of automatic spot welding of workpieces directly in the welding fixtures,

- loading and unloading workpieces with a forklift and crane,

- use of a quick-change system of welding fixtures with parts on the welding positioner,

- the ability to multi-stage welding,

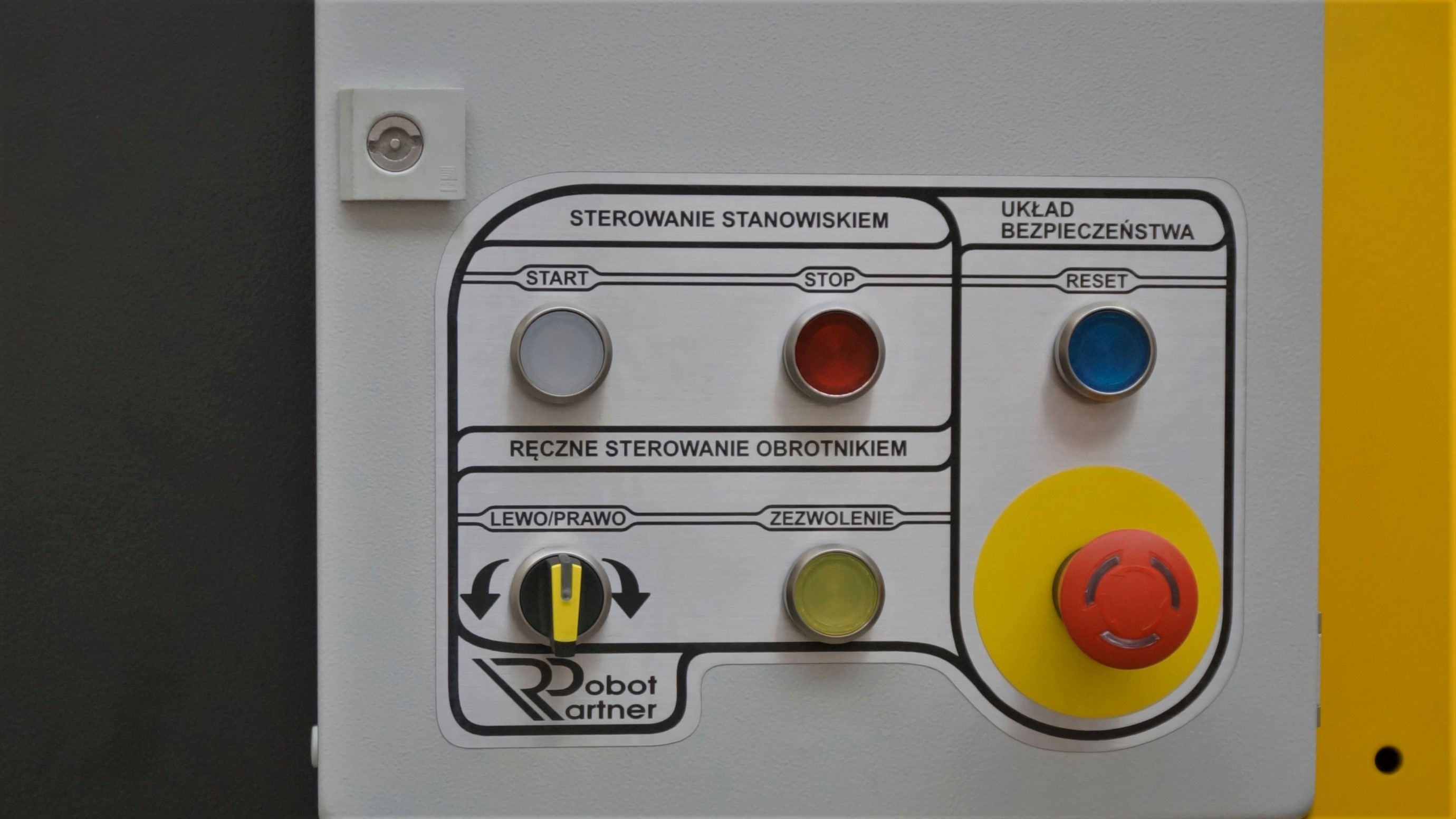

- the possibility of manual control of the welding positioner during loading and unloading of workpieces.

To meet all the requirements, initially we made analysis of parts preparation, possible fixtures for automatic welding and WPS from manual welding. Received results allowed us to choose best technical solutions for robotic welding.

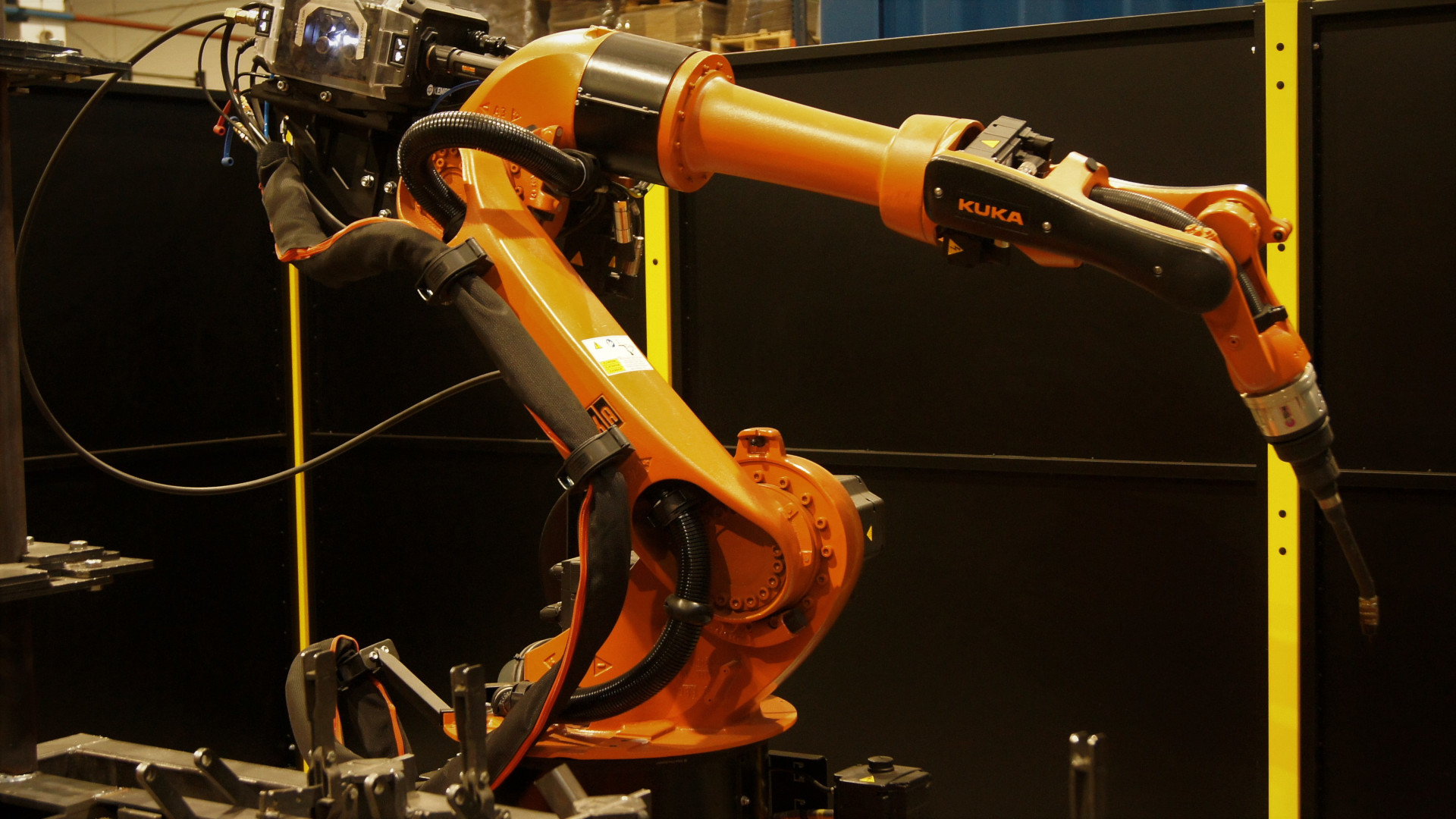

The heart of the station is the KUKA KR16 L8 Arc HW welding robot connected with newest Kemppi A7 450A welding source. The robot is built in the hollow writs technology, which allows for flexible and safe work outside and inside the parts structure. The welding source is equipped with a digital communication interface with the KR C4 robot controller. This combination allows operators to freely set all parameters directly from the SmartPAD touch panel.

A welding positioner with a support frame, mounted directly on the flanges, enables a quick fixtures changes when changing frames in production. Moreover, the “asynchronous mode” allows operators to freely set the loading position of the parts and fixtures. A customized loading gate enables loading and unloading of fixtures and welded parts with a forklift and a crane.

The lengths and overall dimensions of the manufactured parts caused the necessity for the extension of robot’s working range. We met this demand by adding linear unit for robot. The linear unit was developed especially for welding applications. In addition, its design allows for precise movement of the robot without worrying about the impact of spatters and process contaminations on its durability. Within the scope of the project, we integrated Igus energy chains inside linear unit, making compact and safe routing for all wire packages needed for robot without fear of damaging them.

The Torch cleaning and wire cutting station ensuring cleanliness of welding tip and stable TCP. The “collision box”, mounted on the robot flange, protects torch from damage in case of faulty fastening of components or error in programming robot trajectories.

The cell is guarded with a safety fence made of full steel panels and build in additional safety elements. The safety scanner protects operators against accidental starting of the process when they are inside the fence. All security components are supervised by PLC safety controller.

Furthermore, in order to improve the ergonomics of operating the station, we developed a physical control panel, adapted for operation in protective gloves. In addition we developed for the robot additional screens, dedicated to welding processes. This visual interface increase the comfort of use for operators not trained in advanced robot operation and programming.

The automation of the welding process ensured repeatability and enabled achieving higher quality of manufactured parts. Welding efficiency increased as a result of spot welding and full welding processes carried out within one mounting of the workpiece in the fixture on positioner.

Previous Next