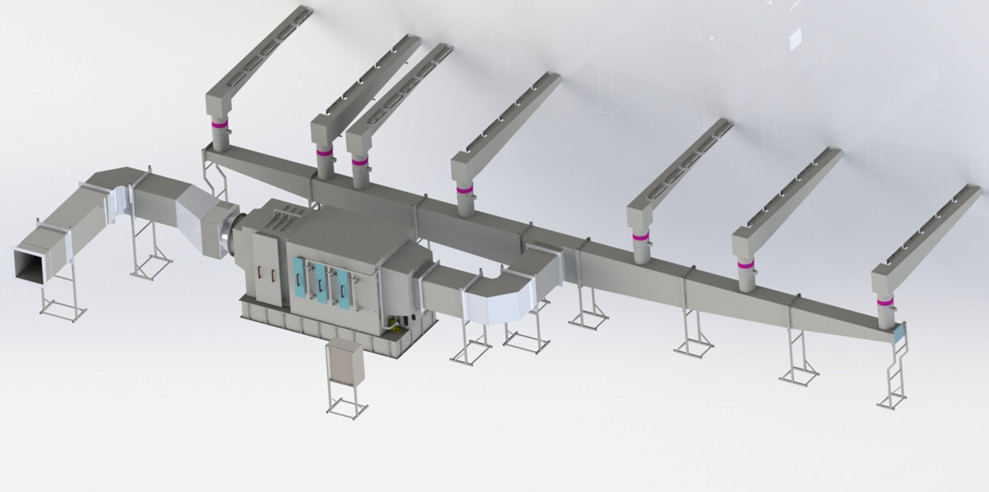

Installation of fumes purification from a tanks complex for galvanic processing of workpieces.

We developed a comprehensive solution for full system of extracting and purifying fumes from electroplating processes. The whole system was developed for the Polish branch of the Canadian company Cyclone Mfg, located in the industrial zone in Krasnik. The key assumptions of the application were based on architectonic conditions and used chemicals:

- system efficiency 30 000 m3/h,

- collecting fumes from 7 technological tanks,

- the whole system is made of chemically resistant technical PVC,

- water fumes filtration ensuring the purity of the filtering water.

For the needs of the application, all components of the installation were designed from ground up, from collectors through exhaust ducts to the individually developed water scrubber. A 21kW radial fan, powered by an inverter, was used to generate the vacuum inside the system. The use of an frequency inverter allowed for energy savings and smooth speed regulation depending on the quantity of active process bathtubs. Additional throttles turned off suction from unused bathtubs to reduce vacuum losses while reducing the stages of processes. Equipping the water scrubber with a mechanical condenser effectively reduced water losses. The physicochemical analyzer controls the saturation of the water and controls mixture by refilling with clean process water to ensure the quality of the purification process.

All components of the installation were made of technical PVC plates, that were cut, processed and then welded with hand welding machines and extruder provided by Leister Company.

Process automation was based on the Siemens S7-1200 PLC and ProfiNET communication. This solution allowed for decentralization of sensor and actuators control as well as moving the HMI control panel to a higher floor near to the bathtub service. The whole line was developed so that there is no need for constant monitoring of parameters by a technologist or service, and the control is based on one operator, who most of the time carries out production processes at the electroplating line.

Previous